How Durable Safety Grating Enhances Workplace Safety: A Comprehensive Guide

Oct 14,2025

How Durable Safety Grating Enhances Workplace Safety

Table of Contents

- 1. Introduction to Safety Grating

- 2. Importance of Workplace Safety

- 3. What is Safety Grating?

- 4. Materials Used in Durable Safety Grating

- 5. Benefits of Using Durable Safety Grating

- 6. Applications of Safety Grating in Various Industries

- 7. Selecting the Right Safety Grating for Your Needs

- 8. Maintenance and Care for Safety Grating

- 9. Conclusion

- 10. Frequently Asked Questions

1. Introduction to Safety Grating

In today's fast-paced industrial environments, the focus on safety cannot be overstated. One key element contributing to workplace safety is the use of **durable safety grating**. This structural material serves as a crucial component in various applications, ensuring that workspaces remain not only functional but significantly safer. By understanding how safety grating enhances workplace safety, organizations can better protect their employees and reduce the risk of accidents.

2. Importance of Workplace Safety

The significance of maintaining a safe working environment extends beyond mere compliance with regulations. A safe workplace improves employee morale, productivity, and overall organizational reputation. According to the Occupational Safety and Health Administration (OSHA), over 4,500 workplace fatalities occur each year in the United States alone. By implementing effective safety measures, businesses can mitigate these risks, protect their workforce, and foster a culture of safety.

3. What is Safety Grating?

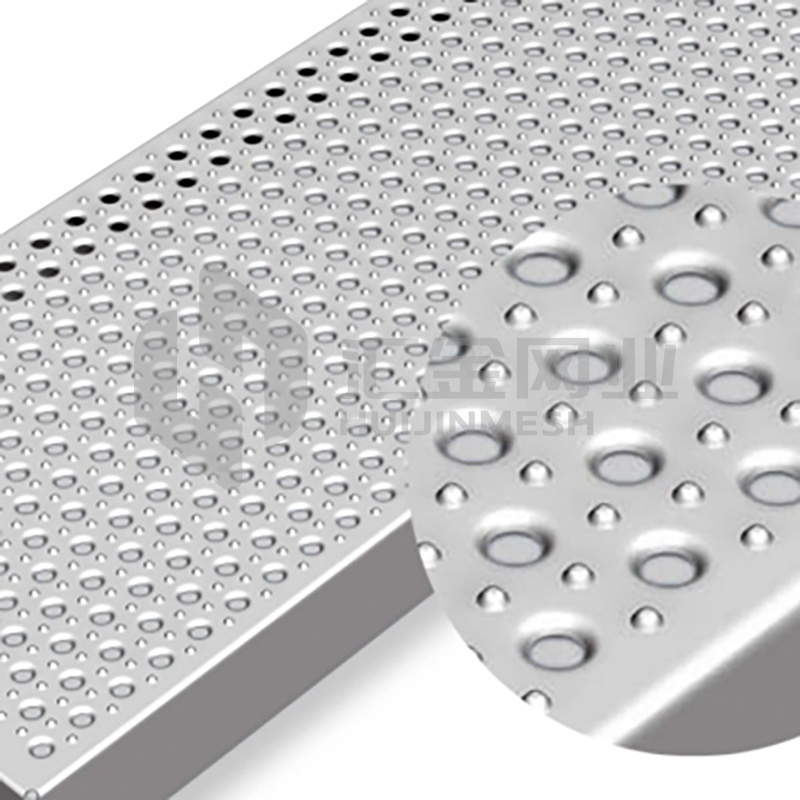

Safety grating refers to a type of flooring or platform material designed to provide a stable walking surface while allowing for drainage and ventilation. Composed of various materials, safety grating solutions are tailored to meet specific performance requirements. This grating is engineered to bear substantial weight loads, resist slipping, and withstand harsh environmental conditions, making it a preferred choice for many industrial applications.

4. Materials Used in Durable Safety Grating

Safety grating comes in several materials, each offering unique characteristics suited for different applications. The most common materials include:

4.1 Steel Grating

Steel grating is known for its strength and durability. It can endure heavy loads and is often used in industrial settings where high traffic is expected.

4.2 Aluminum Grating

Lightweight yet robust, aluminum grating is resistant to corrosion, making it ideal for outdoor applications and environments prone to moisture.

4.3 Fiberglass Reinforced Plastic (FRP) Grating

FRP grating combines the advantages of lightweight design with exceptional strength and chemical resistance. It is commonly used in environments where traditional materials may corrode, providing a long-lasting solution.

5. Benefits of Using Durable Safety Grating

The incorporation of durable safety grating within the workplace offers a multitude of benefits:

5.1 Enhanced Slips and Falls Prevention

The design of safety grating includes features that provide excellent traction, significantly reducing the likelihood of slips and falls. This is particularly crucial in environments that involve moisture, oil, or other hazardous substances.

5.2 Increased Load-Bearing Capacity

Durable safety grating can bear substantial weight, making it suitable for areas that support heavy machinery or equipment. The robust construction ensures safety even under extreme conditions.

5.3 Improved Drainage

Safety grating is designed to allow liquids to flow through, preventing pooling and reducing slipping hazards. This feature is essential in workplaces such as kitchens, factories, and outdoor facilities.

5.4 Easy Installation and Maintenance

Most safety grating systems are straightforward to install, allowing for minimal disruption to operations. Additionally, they require little maintenance, as many materials resist corrosion and wear.

6. Applications of Safety Grating in Various Industries

Durable safety grating finds applications across numerous industries, each benefitting from enhanced safety features:

6.1 Manufacturing Facilities

In manufacturing, safety grating protects workers from potential hazards associated with heavy machinery while providing a durable flooring solution that can withstand high traffic.

6.2 Construction Sites

Construction sites benefit from safety grating due to its load-bearing capacity and slip resistance, making it safe for workers navigating uneven surfaces.

6.3 Commercial Kitchens

In commercial kitchens, safety grating delivers crucial drainage capabilities while minimizing slip risks, contributing to a safer cooking environment.

6.4 Chemical Processing Plants

Safety grating made from FRP is particularly valuable in chemical processing plants, where materials may be corrosive and pose significant safety risks.

7. Selecting the Right Safety Grating for Your Needs

Choosing the appropriate safety grating involves considering several factors:

7.1 Load Requirements

Assess the weight and load capacity necessary for your specific application to ensure the selected grating can adequately support it.

7.2 Environmental Conditions

Consider the environmental factors such as moisture, chemical exposure, and temperature variations when selecting materials.

7.3 Surface Finish

The surface profile is critical for slip resistance. Choose a finish that corresponds to the safety requirements of your operation.

7.4 Compliance Standards

Ensure that your safety grating complies with relevant industry standards and regulations to maintain safety and legal compliance.

8. Maintenance and Care for Safety Grating

Maintaining safety grating is essential for longevity and continued safety effectiveness. Regular inspections and cleaning can help identify wear and ensure that the surfaces remain free of debris that could pose slip hazards.

8.1 Regular Inspections

Conduct routine inspections to identify any signs of wear or damage. Addressing these issues promptly can prevent safety risks.

8.2 Cleaning Protocols

Establish a cleaning protocol to remove dirt, grease, and other substances that could compromise traction. Depending on the material, pressure washing or chemical cleansers may be suitable.

9. Conclusion

Incorporating **durable safety grating** in the workplace is a proactive measure that significantly enhances safety standards. By providing a slip-resistant surface that can handle heavy loads and withstand harsh conditions, safety grating plays a pivotal role in reducing workplace accidents. Choosing the right grating material and ensuring proper maintenance further solidifies its importance in creating a safer work environment. Organizations that prioritize safety through the use of durable safety grating not only protect their employees but also contribute to a more productive and efficient workplace.

10. Frequently Asked Questions

10.1 What types of safety grating are available?

Safety grating is available in various materials, including steel, aluminum, and fiberglass reinforced plastic (FRP), each suited for different applications.

10.2 How can I determine the right load capacity for my safety grating?

Consult the manufacturer's specifications and guidelines to assess load capacities tailored to your specific operational needs.

10.3 Is safety grating resistant to corrosion?

The corrosion resistance varies by material. Aluminum and FRP grating, for instance, often provide superior resistance compared to traditional steel.

10.4 How often should safety grating be inspected?

Regular inspections should be conducted at least quarterly, though high-traffic areas may require more frequent checks.

10.5 Can safety grating be used outdoors?

Yes, many types of safety grating are designed to withstand outdoor conditions, particularly materials like aluminum and FRP, which resist corrosion.

By leveraging the advantages of durable safety grating, organizations can foster a safer work environment, reduce accident rates, and promote employee well-being.