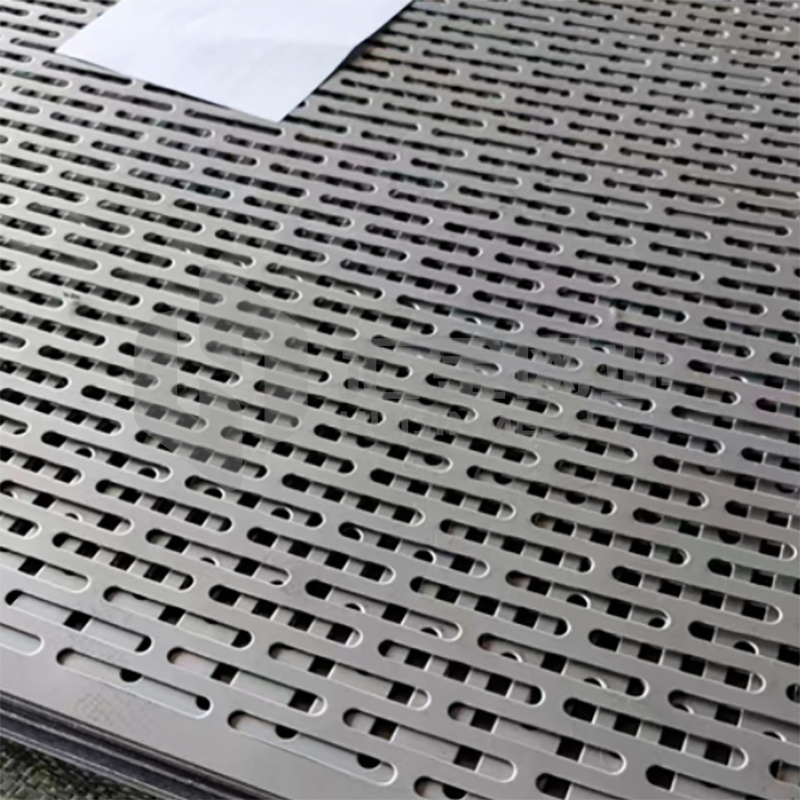

Understanding Slotted Perforated Panels

Jun 15,2025

Slotted perforated panels are versatile components widely utilized in different manufacturing and industrial applications, particularly in metal processing machinery. These panels are characterized by their unique design featuring a series of slots or perforations, which not only reduce weight but also provide enhanced airflow, sound absorption, and aesthetic appeal. When considering a purchase of slotted perforated panels, it is essential to understand their benefits and potential uses.

One of the primary advantages of using slotted perforated panels is their ability to facilitate airflow. In environments where ventilation is crucial—such as in machinery enclosures or industrial workspaces—these panels allow for unrestricted air movement, helping to maintain optimal operating conditions. This can lead to improved efficiency and longevity of equipment, as overheating and excess dust build-up are mitigated.

In addition to their functional benefits, slotted perforated panels can also contribute to sound management. Their unique perforated design can help dampen noise levels in high-decibel environments, making them an excellent choice for industrial settings where noise reduction is a priority. By incorporating these panels into machinery or as partition walls, companies can create a more comfortable working environment for employees.

From a design perspective, slotted perforated panels offer significant aesthetic versatility. They can be customized in various sizes, shapes, and materials, allowing engineers and designers to create tailored solutions that meet specific project requirements. Whether you’re designing a modern manufacturing floor or a machine housing, slotted perforated panels can enhance the overall look and feel of the environment while maintaining functionality.

When sourcing slotted perforated panels, it’s crucial to consider the specific needs of your project. Factors such as material type (aluminum, stainless steel, etc.), thickness, and the dimensions of the slots should be evaluated based on the intended application. Additionally, understanding the manufacturing processes behind these panels can provide insights into their durability and performance, ensuring that you select a product that aligns with your operational demands.

In conclusion, slotted perforated panels are an essential component in the manufacturing and metalworking sectors, offering unique benefits such as improved airflow, sound absorption, and aesthetic appeal. By considering the specific requirements of your applications and understanding the various options available, you can make informed decisions when integrating these panels into your projects. Whether for ventilation, noise reduction, or design purposes, slotted perforated panels can significantly enhance the efficiency and effectiveness of your industrial operations.