Why Safety Grating is Essential for Construction Safety: A Comprehensive Guide

Oct 26,2025

Why Safety Grating is Essential for Construction Safety

The Importance of Safety Grating in Construction

In the construction industry, worker safety is paramount. **Safety grating** serves as a vital component in safeguarding construction sites, helping to prevent slips, trips, and falls. As the industry evolves, the need for effective safety measures has never been more pressing, making safety grating an essential investment for any construction project.

Understanding Safety Grating

Safety grating, also known as **grated flooring**, is a type of flooring system designed to allow for the passage of light, air, and, in some cases, water while providing a stable and safe walking surface. This structured flooring solution is used extensively in various construction environments, including industrial facilities, walkways, and platforms.

Types of Safety Grating

Safety grating comes in several forms, each designed to suit different applications and environments:

1. Steel Grating

Steel grating is one of the most commonly used types of safety grating. It offers **high durability** and the ability to withstand heavy loads, making it ideal for industrial applications. The open design promotes drainage and reduces the risk of water accumulation.

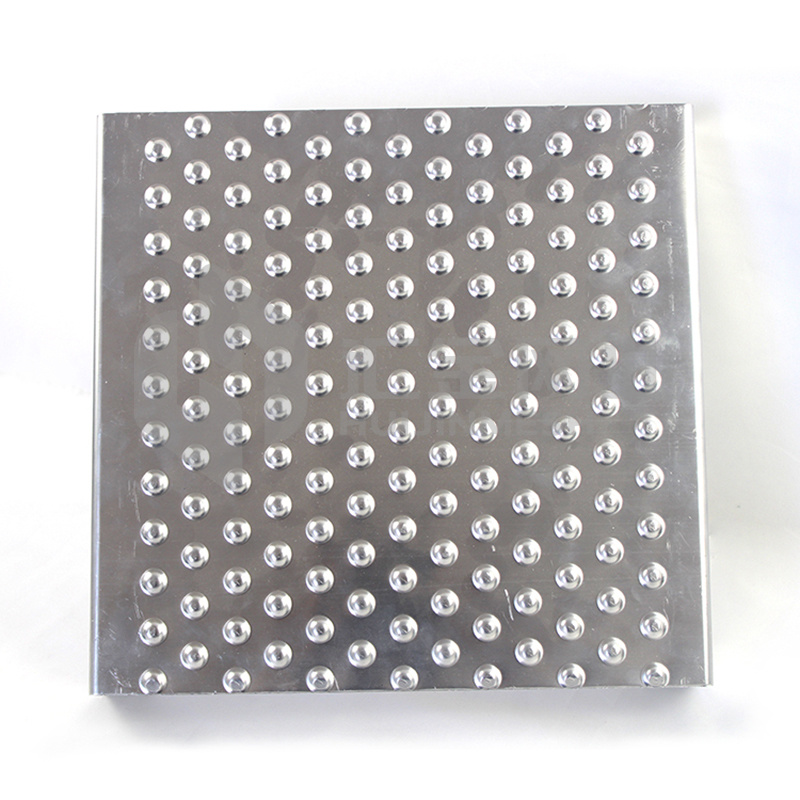

2. Aluminum Grating

Lightweight yet robust, aluminum grating is corrosion-resistant and often used in environments exposed to harsh chemicals. Its lightweight nature makes it easier to install while still providing ample safety features.

3. FRP Grating (Fiberglass Reinforced Plastic)

FRP grating is a non-corrosive alternative to metal grating. It is ideal for environments where chemical exposure is a concern. Additionally, its lightweight properties and ease of installation make it a popular choice in many construction applications.

Key Benefits of Safety Grating

Implementing safety grating on construction sites presents numerous advantages:

1. Enhanced Safety

The primary purpose of safety grating is to provide a secure walking surface that minimizes the risk of accidents. The design of safety grating promotes traction, effectively reducing the chances of slips and falls.

2. Improved Visibility

The open structure of safety grating allows for better visibility on work sites. This feature is particularly beneficial when used in areas with heavy machinery, as it enables operators to maintain visibility of their surroundings.

3. Easy Installation and Maintenance

Safety grating systems are relatively easy to install, requiring minimal maintenance. This ease of use translates to reduced downtime on construction projects, ensuring that work can proceed without unnecessary delays.

4. Versatility

Safety grating can be utilized in a variety of settings, from warehouses to outdoor walkways. Its adaptability enables construction professionals to implement safety measures tailored to specific environments.

Installation of Safety Grating

The proper installation of safety grating is critical to ensuring its effectiveness in providing a safe working environment. Below are the steps involved in installing safety grating:

1. Site Assessment

Before installation, a thorough site assessment must be conducted. Identify high-risk areas where safety grating will be most beneficial and evaluate environmental conditions affecting the choice of grating material.

2. Selecting the Right Type of Grating

Choose the appropriate type of safety grating based on the specific requirements of the project. Consider factors such as load-bearing capacity, environmental exposure, and ease of installation.

3. Preparing the Installation Area

Ensure that the installation area is clean and free from debris. Proper preparation is essential for achieving a stable base for the safety grating.

4. Installing the Grating Units

Follow manufacturer guidelines during installation, ensuring that grating units are aligned correctly and secured tightly. Utilize appropriate hardware and tools for optimal results.

5. Regular Inspections

Post-installation, conduct regular inspections of the safety grating system. Check for signs of wear, corrosion, or damage that could compromise safety.

Best Practices for Maintaining Safety Grating

To ensure the longevity and effectiveness of safety grating systems, adhere to the following best practices:

1. Routine Cleaning

Regular cleaning is essential to maintain the integrity of the safety grating. Remove debris, spills, and other contaminants that could impede traction.

2. Periodic Inspections

Schedule routine inspections to detect any signs of damage or wear. Early identification of issues allows for timely repairs, preventing accidents.

3. Employee Training

Educate workers on the importance of safety grating and proper usage techniques. Empowering employees with knowledge can significantly reduce risks on construction sites.

4. Compliance with Regulations

Stay updated with local safety regulations regarding the use of safety grating. Ensure that all installations meet or exceed industry standards.

Safety Grating in Various Applications

Safety grating can be used in multiple applications across different industries, enhancing safety in various environments:

1. Industrial Facilities

In manufacturing plants and warehouses, safety grating provides safe walking surfaces for workers while allowing for the efficient passage of light and air.

2. Construction Sites

Safety grating is essential on construction sites for walkways, scaffolding, and platforms, promoting worker safety during the building process.

3. Chemical Plants

FRP safety grating is particularly useful in chemical plants, where exposure to corrosive substances presents significant risks. Its non-corrosive properties ensure a safer working environment.

4. Outdoor Applications

Safety grating can be used for outdoor walkways and drainage solutions, enhancing both functionality and safety in public spaces.

FAQs About Safety Grating

1. What is safety grating made of?

Safety grating can be made from various materials, including steel, aluminum, and fiberglass reinforced plastic (FRP), each offering unique benefits depending on the application.

2. How do I choose the right safety grating for my project?

Consider factors such as load-bearing capacity, environmental exposure, and installation requirements when selecting the appropriate type of safety grating for your project.

3. Is safety grating easy to install?

Yes, safety grating systems are designed for easy installation, making them a practical safety solution for construction sites.

4. How can I ensure the longevity of safety grating?

Routine cleaning, periodic inspections, and employee training can help maintain the effectiveness and longevity of safety grating systems.

5. Are there any regulations governing the use of safety grating?

Yes, local safety regulations dictate the use of safety grating to ensure compliance with industry standards and enhance worker safety.

Conclusion

In conclusion, safety grating is not merely an accessory in construction; it is a vital component that enhances workplace safety and efficiency. By understanding the different types of safety grating, their benefits, and the best practices for installation and maintenance, construction professionals can make informed decisions that protect their workforce. Investing in safety grating is an investment in the safety and productivity of any construction project.