Exploring the Benefits of Using Durable Safety Grating in Your Build

Sep 11,2025

Exploring the Benefits of Using Durable Safety Grating in Your Build

Table of Contents

- 1. Introduction to Safety Grating

- 2. What is Safety Grating?

- 3. Types of Safety Grating

- 4. Benefits of Using Durable Safety Grating

- 4.1 Enhanced Safety and Security

- 4.2 Cost-Effectiveness and Longevity

- 4.3 Environmental Sustainability

- 5. Applications of Safety Grating

- 6. Installation and Maintenance of Safety Grating

- 7. Comparison with Other Materials

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to Safety Grating

In the construction and design world, safety cannot be compromised. As we strive to create environments that are both functional and secure, the choice of materials plays a pivotal role. **Safety grating** has emerged as a vital component in various building projects due to its unique attributes. This article delves into the specifics of safety grating, highlighting its benefits, types, and applications, ultimately demonstrating why it is an essential material in any construction endeavor.

2. What is Safety Grating?

Safety grating refers to a type of flooring or platform material that ensures stability, durability, and safety in both commercial and industrial environments. Typically composed of a series of interconnected bars or meshes, safety grating allows for light and air to pass through while providing a secure surface for walking, working, or operating machinery. It's designed to prevent slips, trips, and falls, making it an indispensable choice for high-traffic areas.

3. Types of Safety Grating

When selecting safety grating for your project, it’s essential to understand the different types available, each with unique properties suited for specific applications.

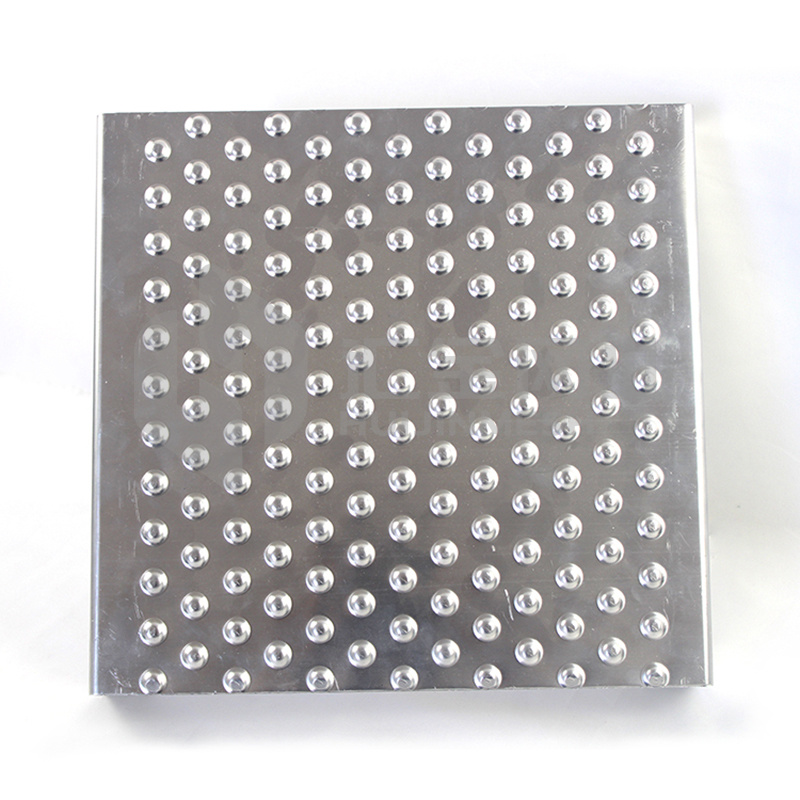

3.1 Metal Grating

Metal grating is one of the most commonly used types, typically made from materials like steel or aluminum. It is known for its strength and durability, making it an excellent choice for heavy-duty industrial settings. Metal grating provides superior load-bearing capabilities and is resistant to corrosion when treated appropriately, ensuring it withstands harsh environments.

3.2 Fiberglass Grating

Fiberglass grating is lightweight and highly resistant to chemicals, moisture, and UV radiation. This makes it ideal for applications in industries such as chemical processing, wastewater treatment, and food and beverage manufacturing. Its non-conductive properties also make it a suitable choice for electrical applications, enhancing safety and efficiency.

3.3 Plastic Grating

Plastic grating, often made from polypropylene or other polymers, offers a cost-effective alternative for various applications. While it may not hold the same load-bearing capabilities as metal or fiberglass options, plastic grating is lightweight, easy to install, and resistant to decay and corrosion. This makes it suitable for light-duty applications, such as in residential settings, landscaping, or as temporary flooring solutions.

4. Benefits of Using Durable Safety Grating

Choosing safety grating for your construction project comes with numerous advantages that extend beyond just safety. Below, we explore some of the most significant benefits.

4.1 Enhanced Safety and Security

Safety grating is designed to minimize hazards in the workplace. The open design allows for natural drainage, reducing the risk of slips from spilled liquids. Additionally, the textured surface provides superior traction, ensuring that workers can navigate areas safely, even in wet or slippery conditions. Using durable safety grating significantly lowers the likelihood of workplace accidents, elevating overall safety standards.

4.2 Cost-Effectiveness and Longevity

Investing in durable safety grating proves to be cost-effective over time. Its robust construction means it requires less frequent replacement than less durable materials. Moreover, many types of safety grating are resistant to corrosion, chemicals, and UV radiation, further extending their lifespan. By minimizing maintenance needs and replacement costs, safety grating can lead to significant savings for businesses in the long run.

4.3 Environmental Sustainability

With growing awareness of environmental issues, it’s crucial to consider the sustainability of construction materials. Many safety grating options, particularly fiberglass and recycled metal grating, are made from environmentally friendly materials. Utilizing long-lasting materials decreases waste generated from frequent replacements and contributes to overall sustainable building practices.

5. Applications of Safety Grating

Safety grating finds applications across various industries, showcasing its versatility and essential role in ensuring safety and functionality.

- **Industrial Facilities**: Used extensively in factories and manufacturing plants for walkways, platforms, and machine guards.

- **Commercial Buildings**: Ideal for stairways, ramps, and balconies in office buildings, schools, and shopping centers.

- **Municipal Infrastructure**: Commonly utilized in pedestrian walkways, bridges, and public transport systems to enhance safety.

- **Marine and Offshore**: Employed on ships and in marine environments where slip resistance and drainage are critical for safety.

6. Installation and Maintenance of Safety Grating

Proper installation and maintenance are essential for maximizing the benefits of safety grating.

**Installation**: Safety grating is relatively easy to install, often requiring only basic tools. Ensure that the grating is securely fastened to prevent movement and provide stability. It's vital to adhere to local building codes and regulations during the installation process.

**Maintenance**: Routine inspections are necessary to identify any potential damage or wear. Cleaning grating surfaces helps to maintain traction and visibility. Depending on the material, specific cleaning agents may be recommended to prevent degradation.

7. Comparison with Other Materials

When evaluating safety grating against other flooring materials, it becomes clear why it is often the superior choice:

- **Concrete**: While concrete is durable, it lacks slip resistance and can become hazardous when wet. Safety grating provides better traction and drainage.

- **Wood**: Wood is susceptible to rot and requires regular maintenance. Safety grating, particularly fiberglass and metal options, offers a longer lifespan with lower upkeep.

- **Carpet**: Although carpet can provide comfort, it does not suit industrial environments where spills and safety concerns are prevalent. Safety grating is a more practical option in such scenarios.

8. Conclusion

Incorporating durable safety grating into your construction projects is not just a matter of compliance; it's a commitment to safety, efficiency, and sustainability. The diverse options available allow for tailored solutions to meet the specific needs of any build. As we've explored, the benefits span enhanced safety, cost-effectiveness, and environmental sustainability, making safety grating a smart choice for modern construction.

9. Frequently Asked Questions

What is safety grating used for?

Safety grating is primarily used in industrial and commercial settings to create safe walking surfaces, platforms, and walkways that reduce the risk of slips and falls.

How does safety grating enhance workplace safety?

The design of safety grating provides better traction and drainage, minimizing slip hazards and ensuring safer navigation in high-traffic areas.

What materials are commonly used for safety grating?

Common materials include metal (steel and aluminum), fiberglass, and plastic, each offering different benefits suited for specific applications.

Is safety grating easy to install?

Yes, safety grating can be installed with basic tools and does not typically require specialized skills. However, following local building codes is essential.

How do I maintain safety grating?

Regular inspections and cleaning are recommended to ensure safety grating remains in good condition. Use appropriate cleaning agents based on the material to avoid damage.

By choosing durable safety grating, you enhance the safety and efficiency of your builds while making a responsible choice for the environment. Embrace the future of construction with safety grating, and watch your projects thrive!