Exploring Round Hole Perforated Metal: A Versatile Solution for Architectural and Decorative Needs

Sep 05,2025

Round hole perforated metal is a remarkable material widely used in the construction and decorative sectors. Its unique properties and versatile applications make it an essential component for architects, designers, and builders alike. This type of metal features uniformly spaced holes, typically circular in shape, allowing for a host of benefits that suit various project requirements.

One of the primary advantages of round hole perforated metal is its ability to provide ventilation and light filtration while maintaining privacy. This is particularly beneficial in applications such as facades, screens, and ceilings, where airflow and natural light play a crucial role in design. The holes allow air to circulate, reducing heat buildup and improving the overall energy efficiency of a building.

In addition to its functional benefits, round hole perforated metal also offers aesthetic value. Its unique patterns can enhance the visual appeal of structures, making it a popular choice for decorative panels and architectural elements. Designers often leverage the versatility of this material to create stunning features that can transform ordinary spaces into extraordinary environments. Importantly, the customization options available—including hole size, spacing, and material type—allow for tailored solutions that meet specific design needs.

Another significant aspect of round hole perforated metal is its durability. Typically made from materials like stainless steel, aluminum, or carbon steel, it is resistant to corrosion and wear, ensuring longevity even in challenging environments. This durability makes it an ideal choice for both indoor and outdoor applications, from commercial buildings to residential spaces.

Installation and maintenance of round hole perforated metal are generally straightforward. With various methods available, including welding, bolting, or using clips, contractors can easily incorporate this material into their projects. Furthermore, maintenance requirements are minimal; a simple cleaning regimen can ensure that the panels retain their aesthetic appeal and functional performance over time.

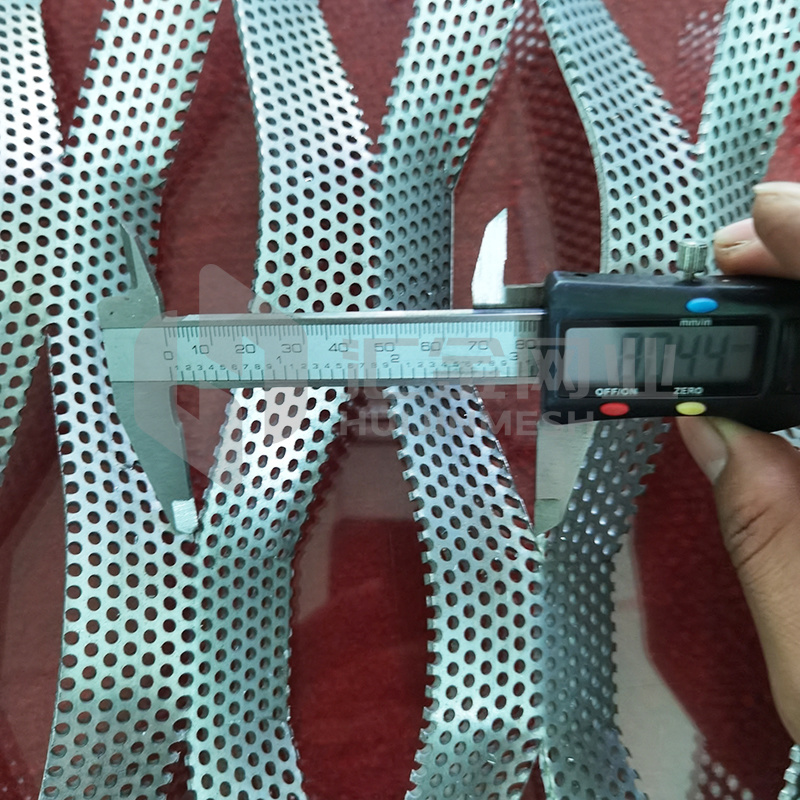

When sourcing round hole perforated metal, it’s essential to consider factors such as material quality, hole size, and thickness. It’s advisable to work with experienced suppliers and manufacturers who understand the nuances of this product and can provide guidance on the best options for your specific project.

In summary, round hole perforated metal stands out as a versatile solution in the building and decoration materials industry. Its ability to combine functionality with aesthetic appeal, alongside its durability and ease of installation, makes it a favored choice for architects and designers. Whether utilized for ventilation, light filtration, or decorative purposes, this material undoubtedly plays a pivotal role in modern architectural practices.

One of the primary advantages of round hole perforated metal is its ability to provide ventilation and light filtration while maintaining privacy. This is particularly beneficial in applications such as facades, screens, and ceilings, where airflow and natural light play a crucial role in design. The holes allow air to circulate, reducing heat buildup and improving the overall energy efficiency of a building.

In addition to its functional benefits, round hole perforated metal also offers aesthetic value. Its unique patterns can enhance the visual appeal of structures, making it a popular choice for decorative panels and architectural elements. Designers often leverage the versatility of this material to create stunning features that can transform ordinary spaces into extraordinary environments. Importantly, the customization options available—including hole size, spacing, and material type—allow for tailored solutions that meet specific design needs.

Another significant aspect of round hole perforated metal is its durability. Typically made from materials like stainless steel, aluminum, or carbon steel, it is resistant to corrosion and wear, ensuring longevity even in challenging environments. This durability makes it an ideal choice for both indoor and outdoor applications, from commercial buildings to residential spaces.

Installation and maintenance of round hole perforated metal are generally straightforward. With various methods available, including welding, bolting, or using clips, contractors can easily incorporate this material into their projects. Furthermore, maintenance requirements are minimal; a simple cleaning regimen can ensure that the panels retain their aesthetic appeal and functional performance over time.

When sourcing round hole perforated metal, it’s essential to consider factors such as material quality, hole size, and thickness. It’s advisable to work with experienced suppliers and manufacturers who understand the nuances of this product and can provide guidance on the best options for your specific project.

In summary, round hole perforated metal stands out as a versatile solution in the building and decoration materials industry. Its ability to combine functionality with aesthetic appeal, alongside its durability and ease of installation, makes it a favored choice for architects and designers. Whether utilized for ventilation, light filtration, or decorative purposes, this material undoubtedly plays a pivotal role in modern architectural practices.