Exploring the Versatility of Decorative Perforated Metal from China: Innovative Applications and Benefits

Aug 09,2025

Exploring the Versatility of Decorative Perforated Metal from China

Introduction to Decorative Perforated Metal

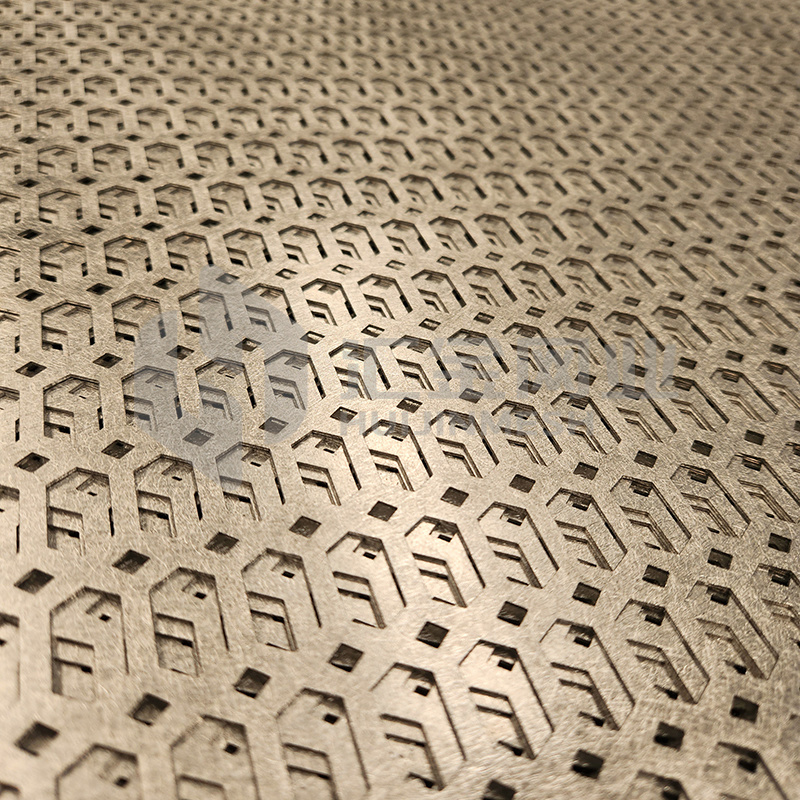

Decorative perforated metal, especially from China, has emerged as a fundamental element in contemporary architecture and design. Its unique characteristics—ranging from aesthetic appeal to functional benefits—make it a preferred choice for various applications. This article delves into the versatility of this material, exploring its benefits, design possibilities, and applications across diverse sectors.

Understanding Perforated Metal: What Is It?

Perforated metal refers to sheets of metal that have been punched with a series of holes, creating patterns that can be both functional and decorative. The process involves various techniques, such as laser cutting, stamping, and punching, allowing for intricate designs and precise hole placements. The use of materials like aluminum, stainless steel, and copper enables manufacturers to produce lightweight yet robust panels suitable for numerous applications.

The Process of Manufacturing Decorative Perforated Metal

The manufacturing process of decorative perforated metal involves several critical steps:

1. **Material Selection**: Choosing the right type of metal is vital for achieving desired properties. Aluminum offers lightweight durability, while stainless steel is known for its corrosion resistance.

2. **Design and Pattern Creation**: Designers utilize computer-aided design (CAD) software to create intricate patterns based on aesthetic and functional requirements.

3. **Punching and Forming**: The design is transferred to sheets of metal through punching machines, creating holes of various shapes and sizes.

4. **Finishing Touches**: Post-production treatments, such as powder coating or anodizing, enhance appearance and protect against environmental factors.

Applications of Decorative Perforated Metal

The versatility of decorative perforated metal allows for a plethora of applications across different industries. Here are some key sectors where this material shines:

1. Architectural Design

In architecture, decorative perforated metal is used for facades, sunshades, and interior partitions. Its ability to filter light while maintaining privacy creates stunning visual effects. The unique designs enhance the building’s aesthetic, making it a popular choice among architects and designers.

2. Interior Decoration

Within interior design, perforated metal panels can serve as room dividers, ceiling tiles, or wall accents. Their modern appeal and customizable designs allow for creative expressions, making spaces feel open yet defined.

3. Urban Spaces and Public Installations

Public art installations and urban furniture often employ decorative perforated metal for seating, shelters, and decorative elements. This material can withstand harsh environmental conditions while providing an artistic touch to public areas.

4. Retail and Commercial Spaces

In retail settings, decorative perforated metal is used for display fixtures, signage, and store fronts. It not only enhances visibility but also allows for airflow, which can be crucial in maintaining product quality.

5. Industrial Applications

In industrial settings, perforated metal serves functional purposes, such as ventilation and filtration systems. Its structural integrity and customization options make it ideal for machinery covers, exhaust systems, and safety barriers.

The Benefits of Using Decorative Perforated Metal

The various advantages of decorative perforated metal further solidify its position as a go-to material in design and architecture.

1. Aesthetic Appeal

One of the primary reasons for using decorative perforated metal is its visual allure. The variety of patterns and finishes available allows for limitless design potential, making it suitable for both modern and traditional aesthetics.

2. Functionality

Beyond aesthetics, perforated metal serves numerous functional purposes, such as light diffusion, sound absorption, and air circulation. Its adaptability to various environmental conditions makes it a practical choice for diverse applications.

3. Durability and Maintenance

Perforated metal is highly durable, withstanding wear and tear better than many alternatives. Appropriate coatings can enhance its resistance to rust and corrosion, ensuring longevity and reducing maintenance needs.

4. Sustainability

Many manufacturers produce perforated metal using recycled materials or employ eco-friendly processes. This aspect appeals to environmentally conscious consumers and businesses looking to minimize their carbon footprint.

5. Customizability

The ability to customize shapes, sizes, and hole patterns enables designers to achieve specific aesthetic and functional goals. This flexibility makes it ideal for projects requiring unique solutions.

Choosing the Right Decorative Perforated Metal

When selecting decorative perforated metal for a project, several factors must be considered:

1. Material Type

Assess the project requirements to determine the best material. For example, aluminum might be suitable for lightweight applications, whereas stainless steel is preferred for outdoor use.

2. Hole Pattern and Size

Choose a hole pattern that aligns with the design intent and functional needs. Variables such as hole size and spacing will affect light transmission and airflow.

3. Finish and Coating

Selecting the right finish enhances both aesthetics and durability. Options like powder coating, anodizing, or galvanizing can offer protection against environmental factors while adding visual appeal.

4. Budget Considerations

Budget constraints can influence material choice and design complexity. It’s essential to balance quality and cost to achieve the desired outcomes without overspending.

Installation Tips for Decorative Perforated Metal

Proper installation is crucial for maximizing the benefits of decorative perforated metal. Consider these tips:

1. Surface Preparation

Ensure that the surface where the metal is being installed is clean, dry, and free of any debris or dirt to facilitate adhesion and stability.

2. Use of Proper Fasteners

Select fasteners that suit the metal type and installation environment. Using high-quality, corrosion-resistant fasteners is essential for longevity.

3. Seek Professional Help

For larger installations or intricate designs, consider hiring professionals. Their expertise ensures that the installation is done correctly and safely.

4. Regular Maintenance

Conduct periodic inspections and maintenance to prevent issues like rust or damage, particularly in outdoor applications.

Common Misconceptions About Decorative Perforated Metal

Despite its growing popularity, several misconceptions about decorative perforated metal persist:

1. Perforated Metal Is Weak

Many believe that perforated metal lacks strength due to the holes. On the contrary, when properly designed and manufactured, it maintains excellent structural integrity.

2. Limited Design Options

Some think that perforated metal offers limited aesthetics. However, with advances in technology, the range of patterns and finishes available is vast and continually evolving.

3. Difficult to Maintain

While some may assume that decorative perforated metal requires extensive upkeep, in reality, its durability and protective coatings simplify maintenance significantly.

Frequently Asked Questions (FAQs)

1. What materials can be used for decorative perforated metal?

Decorative perforated metal can be made from various materials, including aluminum, stainless steel, copper, and carbon steel, each offering unique properties.

2. Can perforated metal be customized?

Yes, perforated metal is highly customizable in terms of material, hole size, pattern, and surface finish, allowing for tailored solutions to meet specific design needs.

3. Is perforated metal suitable for outdoor use?

Absolutely. With appropriate coatings, perforated metal can withstand environmental conditions, making it ideal for outdoor applications.

4. How does perforated metal aid in sound absorption?

Perforated metal can be engineered to absorb sound, depending on the hole size and arrangement, making it a suitable choice for acoustic panels in commercial spaces.

5. What are the cost factors associated with decorative perforated metal?

Cost considerations include the choice of material, complexity of design, size of the panels, and finishing options. Customization may also impact pricing.

Conclusion

Decorative perforated metal from China is a versatile, functional, and aesthetic material that caters to the evolving demands of modern design and architecture. Its applications span a wide range of industries, offering innovative solutions that balance beauty and practicality. As the market continues to grow, understanding the benefits, customization options, and proper installation techniques will empower designers and architects to create breathtaking spaces that make a lasting impression. With this knowledge, one can confidently leverage the unique properties of decorative perforated metal to elevate any project.