Why Buying Slotted Perforated Panels is Essential for Your Manufacturing Needs

May 31,2025

Why Buying Slotted Perforated Panels is Essential for Your Manufacturing Needs

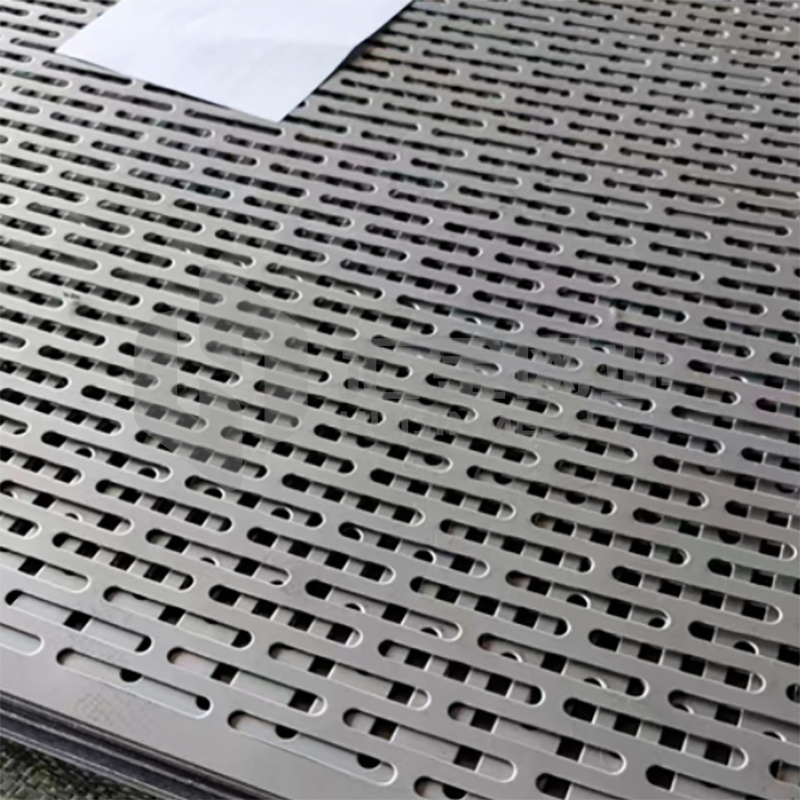

In the realm of manufacturing, efficiency and versatility are paramount. One component that stands out for its multi-faceted applications and benefits is the **slotted perforated panel**. These panels are more than just functional; they are transformative elements that can streamline your manufacturing processes. This article delves into why investing in slotted perforated panels is not just a choice but a necessity for modern manufacturing.

Understanding Slotted Perforated Panels

Before we explore their benefits, it's crucial to understand what slotted perforated panels are. These panels are typically made from materials like metal or plastic and feature a series of slots or holes. This design allows for better airflow, drainage, and visibility, making them ideal for various applications in manufacturing.

Types of Slotted Perforated Panels

Knowing the different types of slotted perforated panels can aid in making the right choice for your needs.

1. Metal Slotted Panels

Metal panels, often made from stainless steel or aluminum, are known for their durability and strength, making them perfect for heavy-duty applications.

2. Plastic Slotted Panels

Plastic options are lightweight and resistant to corrosion, offering an excellent alternative in environments where rust is a concern.

3. Customizable Panels

Many manufacturers offer customizable slotted panels, allowing you to choose the size, shape, and slot pattern that best fits your specific needs.

Benefits of Slotted Perforated Panels in Manufacturing

Slotted perforated panels provide a range of benefits that can significantly enhance your manufacturing processes. Here are some of the key advantages:

1. Enhanced Airflow and Cooling

Proper airflow is critical in manufacturing environments, especially where machinery generates heat. Slotted perforated panels enhance ventilation, helping maintain optimal temperatures and preventing overheating, which can lead to equipment failure.

2. Improved Visibility

In a manufacturing setup, clear visibility is essential for monitoring operations. Slotted perforated panels allow workers to see through the panels, ensuring they can supervise processes without obstruction.

3. Versatility in Application

These panels are not limited to one function. They can serve as:

- **Safety guards** to protect sensitive equipment.

- **Storage solutions** for organizing tools and materials.

- **Partitions** in manufacturing spaces to define areas without completely closing them off.

4. Cost-Effectiveness

Investing in slotted perforated panels can lead to cost savings in the long run. Their durable nature reduces the need for frequent replacements, and the enhanced airflow can lead to lower cooling costs.

5. Easy Installation and Maintenance

Most slotted perforated panels are designed for easy installation, which means less downtime during setup. Their low-maintenance requirements further enhance their appeal, allowing manufacturers to focus on production rather than upkeep.

Applications of Slotted Perforated Panels in Manufacturing

The versatility of slotted perforated panels makes them suitable for various applications in the manufacturing sector.

1. Machine Guards

Using slotted panels as machine guards not only ensures safety but also allows workers to observe machinery in operation, facilitating timely interventions when necessary.

2. Shelving and Storage Solutions

These panels can be used to create shelving units that are both functional and aesthetically pleasing, helping organize tools and materials efficiently.

3. Wall Partitions

In open-floor manufacturing environments, slotted perforated panels can act as partitions that provide a degree of separation without hindering workflow.

4. Acoustic Panels

In noisy manufacturing environments, slotted perforated panels can help manage sound levels by acting as acoustic barriers.

Selecting the Right Slotted Perforated Panels

When choosing slotted perforated panels, several factors should be considered to ensure you make the best decision for your manufacturing needs.

1. Material Selection

Choose the material that best fits your environment. For instance, metal panels are ideal for high-temperature areas, while plastic panels may be better suited for corrosive environments.

2. Slot Size and Pattern

Consider the size and pattern of the slots. Larger slots might facilitate better airflow, while smaller slots can be used for applications requiring more filtration.

3. Panel Thickness

Panel thickness can impact durability and performance. Thicker panels typically offer greater strength and longevity.

4. Customization Options

If standard panels do not meet your requirements, consider customizable options to ensure you get the perfect fit for your application.

Installation and Maintenance of Slotted Perforated Panels

Proper installation and ongoing maintenance are crucial to maximizing the benefits of slotted perforated panels.

1. Installation Process

Most slotted perforated panels come with pre-drilled holes for easy installation. Ensure that you follow the manufacturer's guidelines to secure panels correctly.

2. Regular Inspections

Routine inspections can help identify wear and tear. Regularly check for any signs of damage, especially in high-traffic areas.

3. Cleaning and Maintenance

Depending on the material, cleaning requirements may vary. Generally, a simple wipe down with appropriate cleaning agents will suffice to keep the panels in good condition.

Case Studies: Success Stories of Using Slotted Perforated Panels

Numerous manufacturers have reaped the benefits of incorporating slotted perforated panels into their operations.

1. Automotive Manufacturing

An automotive manufacturer implemented slotted perforated panels in their assembly line to enhance ventilation. This change resulted in a significant reduction in machinery overheating incidents and increased productivity.

2. Electronics Production

A leading electronics company utilized slotted perforated panels for tool storage. The result was a 30% improvement in organization, leading to faster production times and reduced material waste.

Frequently Asked Questions (FAQs)

1. What are slotted perforated panels made of?

Slotted perforated panels can be made from various materials, including metal (such as stainless steel or aluminum) and plastic.

2. How do slotted perforated panels improve airflow?

The slots or holes in the panels allow air to flow freely through, enhancing ventilation and preventing overheating in manufacturing environments.

3. Can slotted perforated panels be customized?

Yes, many manufacturers offer customizable options for slotted perforated panels, allowing you to select size, shape, and slot patterns to meet your specific needs.

4. How do I maintain slotted perforated panels?

Routine inspections and simple cleaning with appropriate solutions are generally sufficient to maintain slotted perforated panels.

5. Are slotted perforated panels suitable for outdoor use?

Yes, slotted perforated panels made from corrosion-resistant materials can be used outdoors, although additional care might be needed depending on the environment.

Conclusion

Investing in slotted perforated panels is an essential decision for any manufacturing operation looking to enhance efficiency, safety, and versatility. Their applications are vast, ranging from machine guarding to storage solutions, making them a valuable asset in any industrial setting. With proper selection, installation, and maintenance, these panels can significantly improve your manufacturing processes, driving productivity and cost savings. By understanding their benefits and applications, you can make informed decisions that will ultimately lead to a more streamlined and successful manufacturing operation.