Discover the Advantages of Slotted Perforated Panels in Metal Processing

May 01,2025

Discover the Advantages of Slotted Perforated Panels in Metal Processing

Table of Contents

- 1. Introduction to Slotted Perforated Panels

- 2. What Are Slotted Perforated Panels?

- 3. Benefits of Using Slotted Perforated Panels in Metal Processing

- 3.1 Enhanced Efficiency in Production

- 3.2 Reduced Waste and Resource Conservation

- 3.3 Improved Airflow and Ventilation

- 3.4 Versatility in Applications

- 3.5 Cost-Effectiveness and Long-term Savings

- 4. Applications of Slotted Perforated Panels in Metal Processing

- 5. Material Options for Slotted Perforated Panels

- 6. Installation and Maintenance of Slotted Perforated Panels

- 7. Future Trends in Metal Processing and Slotted Perforated Panels

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Slotted Perforated Panels

In the ever-evolving landscape of metal processing, efficiency, versatility, and sustainability are paramount. One innovative solution that stands out in achieving these objectives is **slotted perforated panels**. These panels are not just functional; they also represent a modern approach to enhancing the manufacturing process. By integrating slotted perforated panels into your operations, you can unlock numerous advantages that contribute to superior product quality and operational effectiveness.

2. What Are Slotted Perforated Panels?

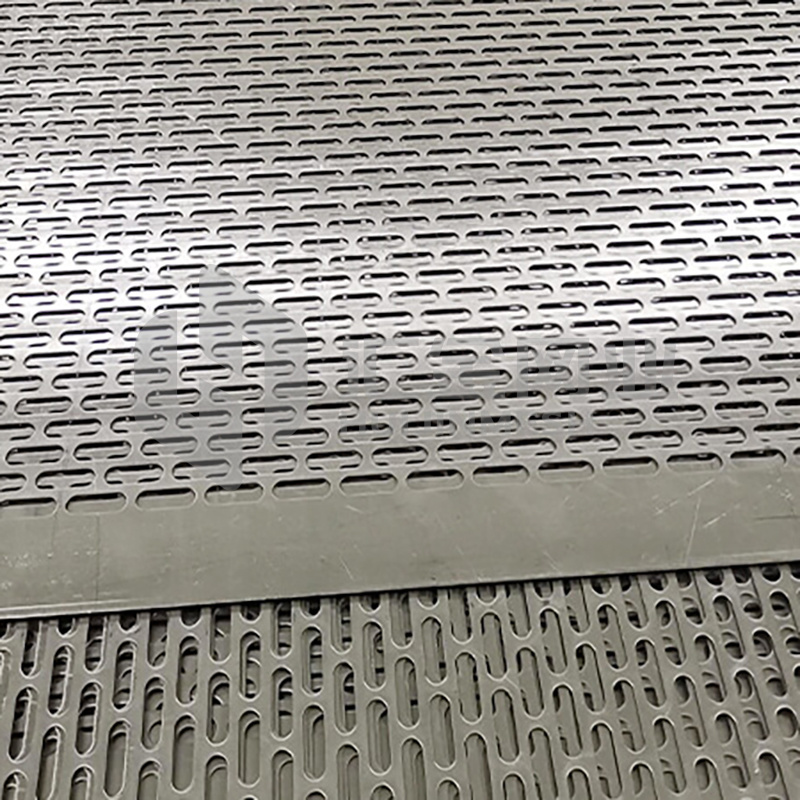

Slotted perforated panels are sheets of material, typically metal, that feature a series of uniformly spaced slots or holes. These slots can vary in size, shape, and spacing depending on the application requirements. The design allows for the passage of air, liquid, or light while maintaining structural integrity. Common materials used for these panels include steel, aluminum, and stainless steel, each offering unique properties tailored to specific industrial needs.

3. Benefits of Using Slotted Perforated Panels in Metal Processing

3.1 Enhanced Efficiency in Production

Implementing slotted perforated panels in metal processing can significantly enhance production efficiency. Their design facilitates optimal airflow and cooling during welding and machining processes. This means equipment can operate at optimal temperatures, reducing the risk of overheating, which in turn extends the lifespan of machinery. Furthermore, the panels allow for more streamlined operations, as they can be easily integrated into existing systems, minimizing downtime during installation.

3.2 Reduced Waste and Resource Conservation

One of the most compelling benefits of slotted perforated panels is their contribution to waste reduction and resource conservation. By improving airflow and efficiency, these panels lead to lower energy consumption during operations. Additionally, their ability to support better filtration and separation processes means that less material is wasted during production. This not only helps reduce operational costs but also promotes a more sustainable approach to manufacturing.

3.3 Improved Airflow and Ventilation

Effective ventilation is crucial in any metal processing facility. Slotted perforated panels enhance airflow, ensuring that heat and fumes are effectively managed. This results in a safer working environment for employees and helps maintain the integrity of sensitive machinery. Improved airflow also contributes to better coating and finishing processes, yielding higher quality products that meet stringent industry standards.

3.4 Versatility in Applications

The versatility of slotted perforated panels makes them suitable for a wide range of applications within the metal processing industry. They can be utilized in various stages of production, from material handling to product assembly and finishing. Whether used as part of a filtration system, in soundproofing applications, or as structural components, these panels adapt to the specific needs of diverse projects, making them an invaluable asset in any workshop or manufacturing setup.

3.5 Cost-Effectiveness and Long-term Savings

Investing in slotted perforated panels can lead to significant long-term savings. Their durability and low maintenance requirements translate into reduced replacement and repair costs. Additionally, the enhanced efficiency and resource conservation that slotted perforated panels provide can lead to lower operational expenses. Businesses can enjoy improved profit margins while also contributing positively to environmental sustainability.

4. Applications of Slotted Perforated Panels in Metal Processing

Slotted perforated panels find a myriad of applications in metal processing and beyond.

- Filtration Systems: Used in various filtration processes, these panels enhance separation efficiency by allowing precise airflow and fluid flow.

- Sound Absorption: In environments where noise reduction is essential, slotted perforated panels can help absorb sound, improving workplace comfort.

- Architectural Features: Beyond industrial applications, these panels are increasingly used in architectural designs for aesthetic appeal while providing functional benefits.

- Heat Management: They play a crucial role in managing heat generation by facilitating airflow around hot machinery.

- Storage Racks: Many manufacturers utilize slotted perforated panels in shelving and storage systems for better organization and accessibility of materials.

5. Material Options for Slotted Perforated Panels

Choosing the right material for slotted perforated panels is essential for optimal performance. Common options include:

- Steel: Highly durable and cost-effective, steel panels are ideal for heavy-duty applications.

- Aluminum: Lightweight and resistant to corrosion, aluminum panels are perfect for applications where weight is a concern.

- Stainless Steel: Known for its resistance to rust and high temperatures, stainless steel is suitable for environments that require stringent hygiene standards.

Each material brings its unique benefits, and the selection should align with the specific operational requirements and environmental conditions of the processing facility.

6. Installation and Maintenance of Slotted Perforated Panels

Installing slotted perforated panels is a straightforward process that can be integrated into existing systems with minimal disruption. Proper installation ensures that the panels function effectively and contribute to enhanced productivity. Maintenance typically involves routine cleaning to prevent the accumulation of dust and debris, which can obstruct airflow. Regular inspections help identify any wear or damage that may require prompt attention, ensuring that the panels continue to perform at their best.

7. Future Trends in Metal Processing and Slotted Perforated Panels

As the metal processing industry evolves, slotted perforated panels are expected to play an increasingly prominent role. With the growing emphasis on sustainability and efficiency, advancements in material technology may lead to even more innovative applications of these panels. Moreover, as automation and smart manufacturing become more prevalent, slotted perforated panels may be integrated into advanced systems to optimize production and enhance operational insights.

8. Frequently Asked Questions

1. What are the main advantages of slotted perforated panels in metal processing?

The key benefits include enhanced efficiency, reduced waste, improved airflow, versatility in applications, and cost-effectiveness.

2. Can slotted perforated panels be customized for specific applications?

Yes, slotted perforated panels can be customized in terms of material, size, and slot configuration to meet specific operational requirements.

3. How do slotted perforated panels contribute to sustainability in manufacturing?

They promote resource conservation, reduce energy consumption, and minimize waste during production processes, aligning with sustainable manufacturing practices.

4. What materials are best suited for slotted perforated panels?

Common materials include steel for durability, aluminum for lightweight applications, and stainless steel for environments requiring high corrosion resistance.

5. How often should slotted perforated panels be maintained?

Routine maintenance is recommended, which includes regular cleaning and inspections to ensure optimal performance.

9. Conclusion

Slotted perforated panels are revolutionizing the metal processing industry by offering a multitude of benefits that enhance production efficiency, reduce waste, and improve workplace safety. Their versatility and adaptability make them indispensable in various applications, from filtration systems to architectural designs. By choosing the right materials and ensuring proper installation and maintenance, businesses can leverage the advantages of slotted perforated panels to achieve significant long-term savings and operational success. Embracing this innovation is not just a step forward; it is a commitment to excellence in metal processing.