Quality Traction Tread Grating: The Perfect Choice for Wet Environments

Apr 25,2025

Quality Traction Tread Grating: The Perfect Choice for Wet Environments

In environments prone to moisture, selecting the right materials is crucial for safety and functionality. **Quality Traction Tread Grating** stands out as an exceptional choice for preventing slips and falls while providing structural integrity. This article delves into the characteristics, advantages, and applications of this versatile grating type, ensuring you understand why it’s the preferred option for various industries.

Table of Contents

- Understanding Traction Tread Grating

- Benefits of Quality Traction Tread Grating

- Applications of Traction Tread Grating in Wet Environments

- Materials Used in Traction Tread Grating

- Installation Process of Traction Tread Grating

- Maintenance and Care for Traction Tread Grating

- Cost-Effectiveness of Using Traction Tread Grating

- Conclusion

- FAQs About Quality Traction Tread Grating

Understanding Traction Tread Grating

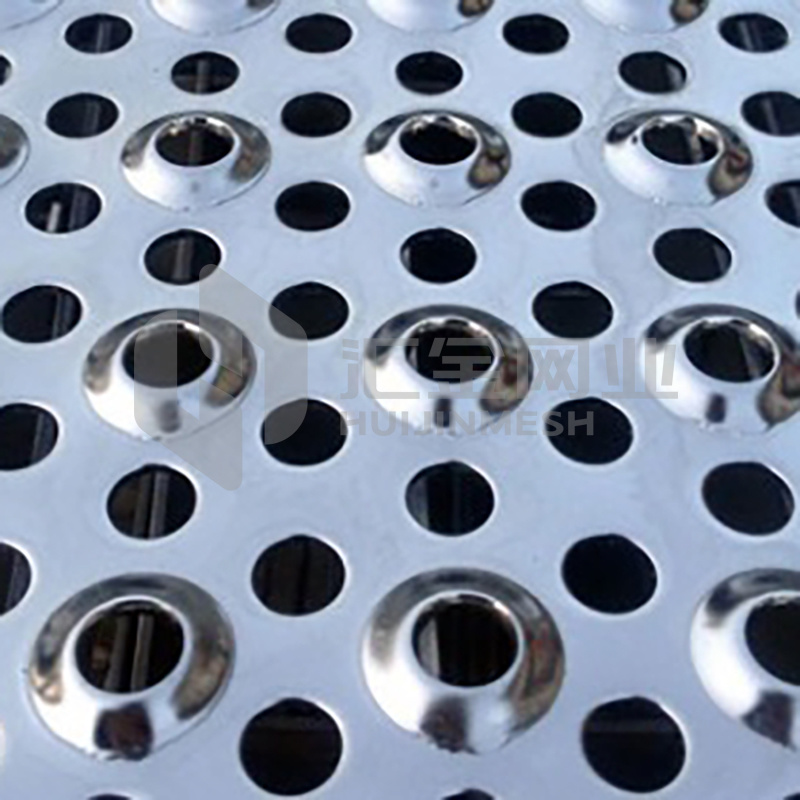

**Traction tread grating** is a specialized type of flooring material designed for areas that experience high foot traffic and wet conditions. It typically features a series of grooves or treads that enhance grip, significantly reducing the risk of slips. This kind of grating is made from various materials, including fiberglass, aluminum, and steel, each offering unique benefits suited for specific environments.

The Importance of Traction in Wet Environments

In wet environments, the risk of accidents increases dramatically. Water, oil, and other liquids can create hazardous conditions that lead to slips and falls. **Quality traction tread grating** incorporates innovative design features that enhance traction, providing a safer walking surface for employees and visitors alike.

Benefits of Quality Traction Tread Grating

Choosing **quality traction tread grating** for your projects offers numerous advantages:

1. Enhanced Safety

The primary benefit is improved safety. The textured surface minimizes slipping, making it an ideal choice for factories, warehouses, and outdoor pathways that frequently get wet.

2. Durability and Longevity

Constructed from robust materials, traction tread grating is designed to withstand heavy loads and harsh environmental conditions. This durability ensures long-term use without the need for frequent replacements.

3. Easy Installation

Traction tread grating is relatively easy to install, requiring minimal tools and expertise. This efficiency can save both time and labor costs during installation.

4. Low Maintenance Requirements

Once installed, this grating requires minimal maintenance. Regular cleaning is usually sufficient to keep the surface clear of debris and potential slip hazards.

5. Versatility in Applications

From industrial applications to commercial and residential settings, traction tread grating can be adapted for various uses, making it a versatile solution for many projects.

Applications of Traction Tread Grating in Wet Environments

Quality traction tread grating is suitable for a wide range of applications:

1. Industrial Facilities

In manufacturing plants, traction tread grating provides a safe walking surface in areas where spills are likely to occur, such as near machinery or in storage areas.

2. Commercial Kitchens

Restaurants and food processing facilities benefit from traction tread grating in kitchens where water and oil spills are common, protecting staff and customers from slips.

3. Outdoor Walkways

Traction tread grating is ideal for outdoor environments, such as parks, docks, and playgrounds, where wet conditions can lead to hazards.

4. Wet Areas in Residential Settings

Homeowners can install traction tread grating in areas like pools, patios, and garages, enhancing safety for family and guests.

5. Transportation Hubs

Airports and train stations can benefit from this type of grating, ensuring passenger safety during rainy weather while maintaining high foot traffic levels.

Materials Used in Traction Tread Grating

Traction tread grating is typically made from three primary materials:

1. Fiberglass

Fiberglass grating is lightweight yet robust, resistant to corrosion and chemicals, making it an excellent choice for wet environments.

2. Aluminum

Aluminum grating is known for its strength and lightweight properties. It’s also resistant to rust, which is critical in environments exposed to moisture.

3. Steel

Steel traction tread grating is incredibly durable and can support heavy loads. It is often coated to prevent rust and to enhance its slip-resistant properties.

Installation Process of Traction Tread Grating

The installation of quality traction tread grating is a straightforward process:

1. Surface Preparation

Ensure that the surface where the grating will be installed is clean and level. Any debris or uneven areas should be addressed before proceeding.

2. Measurement and Cutting

Measure the area to determine how much grating is needed. Use appropriate tools to cut the grating to fit the space accurately.

3. Securing the Grating

Use screws or clips to secure the grating to the surface. Ensure a tight fit to reduce movement and increase safety.

4. Final Inspection

After installation, inspect the grating to ensure it is level and secure. This step is crucial for maintaining safety standards.

Maintenance and Care for Traction Tread Grating

To ensure longevity, proper maintenance of traction tread grating is essential:

1. Regular Cleaning

Regularly sweep or use a hose to clean the surface, preventing the accumulation of dirt and debris that could create slip hazards.

2. Inspect for Damage

Periodically check for signs of wear or damage. Address any issues promptly to maintain safety and integrity.

3. Treating for Corrosion

If using metal grating, apply protective coatings as necessary to prevent rust formation, especially in coastal or industrial areas.

Cost-Effectiveness of Using Traction Tread Grating

Investing in quality traction tread grating can be cost-effective in the long run:

1. Reduced Accidents

By minimizing slip and fall accidents, businesses can save significantly on insurance costs and potential litigation.

2. Durability Leads to Savings

The longevity of traction tread grating means fewer replacements, reducing overall material costs over time.

3. Low Maintenance Costs

With straightforward maintenance requirements, ongoing costs remain low, making traction tread grating a financially sound choice.

Conclusion

**Quality Traction Tread Grating** is an essential solution for any wet environment, combining safety, durability, and versatility. Its ability to reduce slip hazards while maintaining structural integrity makes it a top choice for various applications. By investing in this reliable grating type, you are protecting individuals, enhancing productivity, and ensuring compliance with safety standards. Whether for industrial, commercial, or residential use, opting for quality traction tread grating is a decision that pays off in safety and savings.

FAQs About Quality Traction Tread Grating

1. What is traction tread grating made from?

Traction tread grating can be made from various materials, including fiberglass, aluminum, and steel, each providing unique benefits for different applications.

2. How does traction tread grating enhance safety?

The textured surfaces of traction tread grating increase grip, significantly reducing the chances of slips and falls in wet conditions.

3. Where can I use traction tread grating?

It is suitable for various environments, including industrial facilities, commercial kitchens, outdoor walkways, residential areas, and transportation hubs.

4. How do I maintain traction tread grating?

Regular cleaning and periodic inspections are essential to ensure safety and longevity. Treat any signs of damage or wear immediately.

5. Is traction tread grating cost-effective?

Yes, although it may have an upfront cost, its durability, low maintenance requirements, and accident prevention features make it a cost-effective solution in the long term.